Fuel filler & charging ports

Comprehensive polymer assemblies,

tailor-made for our customers, highlight our expertise in the field of visible components.

From Development to Logistics Everything under one roof

Thanks to our experienced development team, modern technological facilities, and extensive employee potential, we can meet the needs of our customers for both Build-to-Print and Build-to-Spec production processes.

Complete development according to customer requirements

Testing in our modern test center, meeting all required standards

Design of the best production solution based on customer needs

Development and production of our own manufacturing lines for the product

Trial production series

Full serial production of the developed product

Advanced logistics services (JIT, JIS)

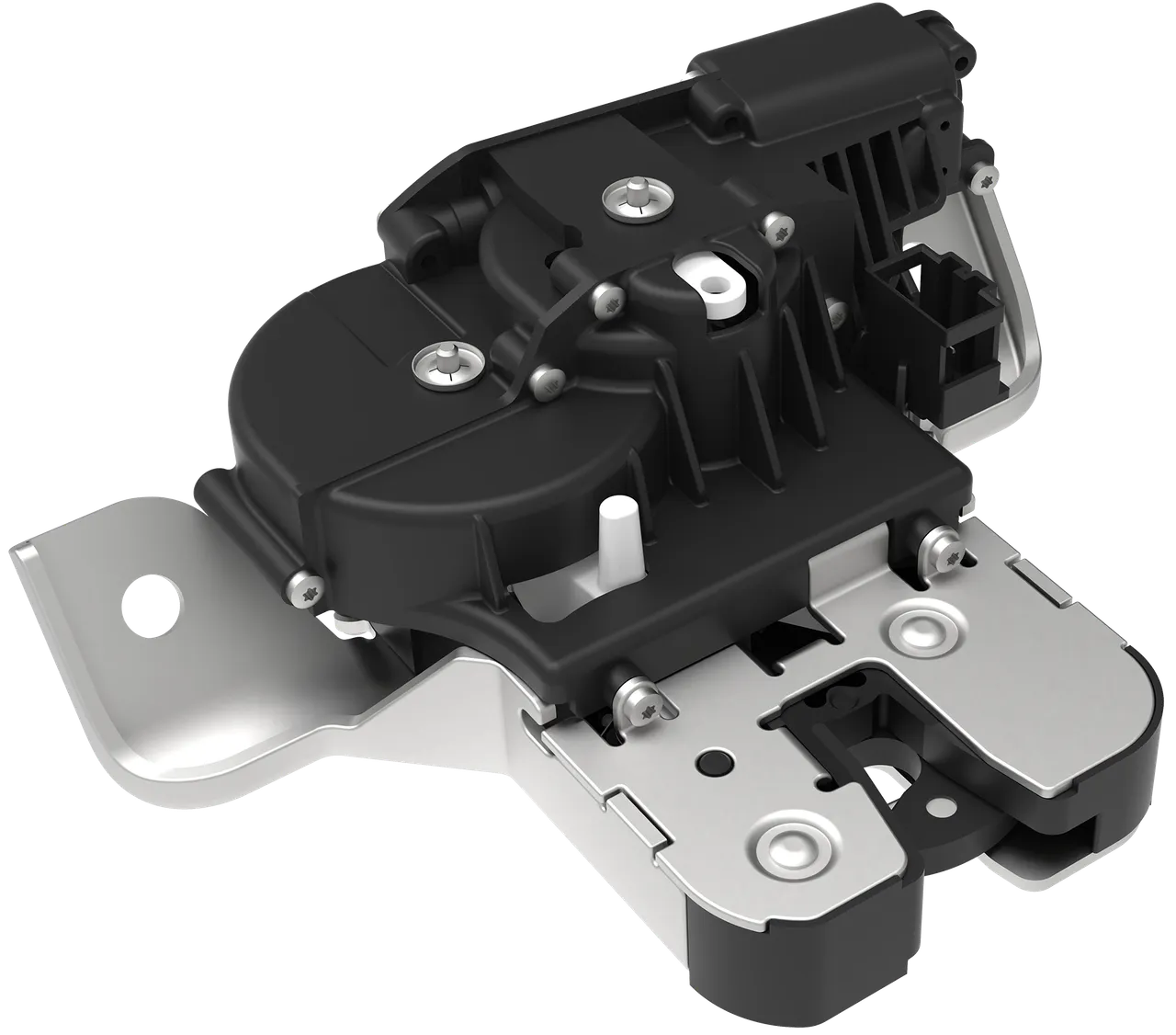

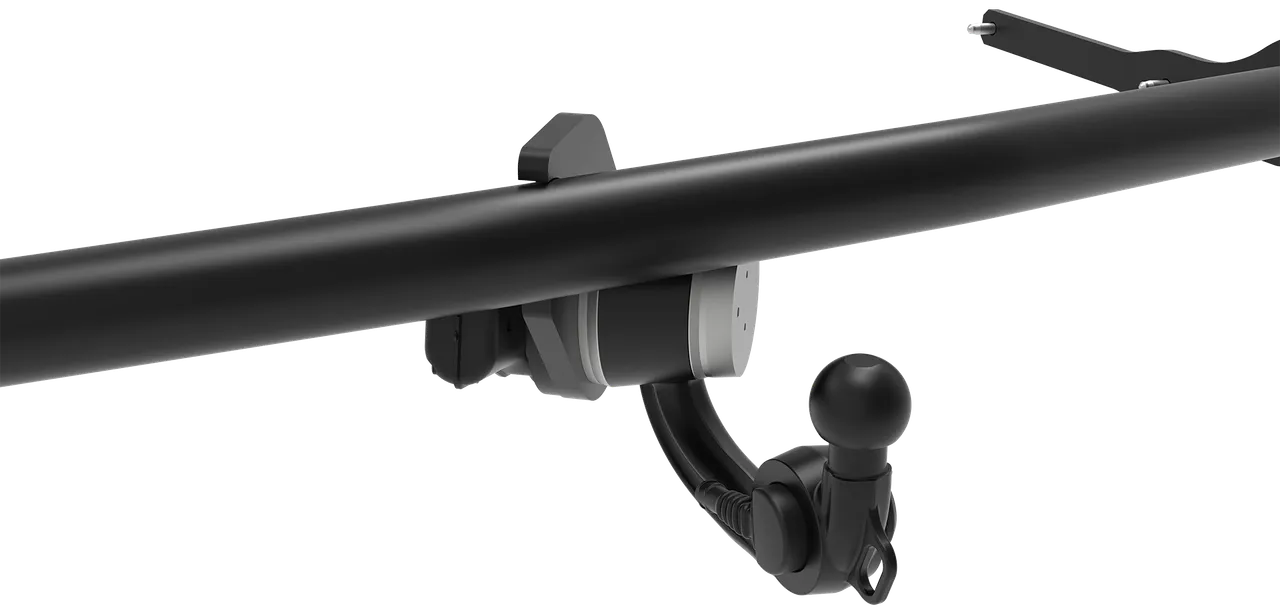

Manual fuel-filler modules

Safe and convenient fuel system opening.

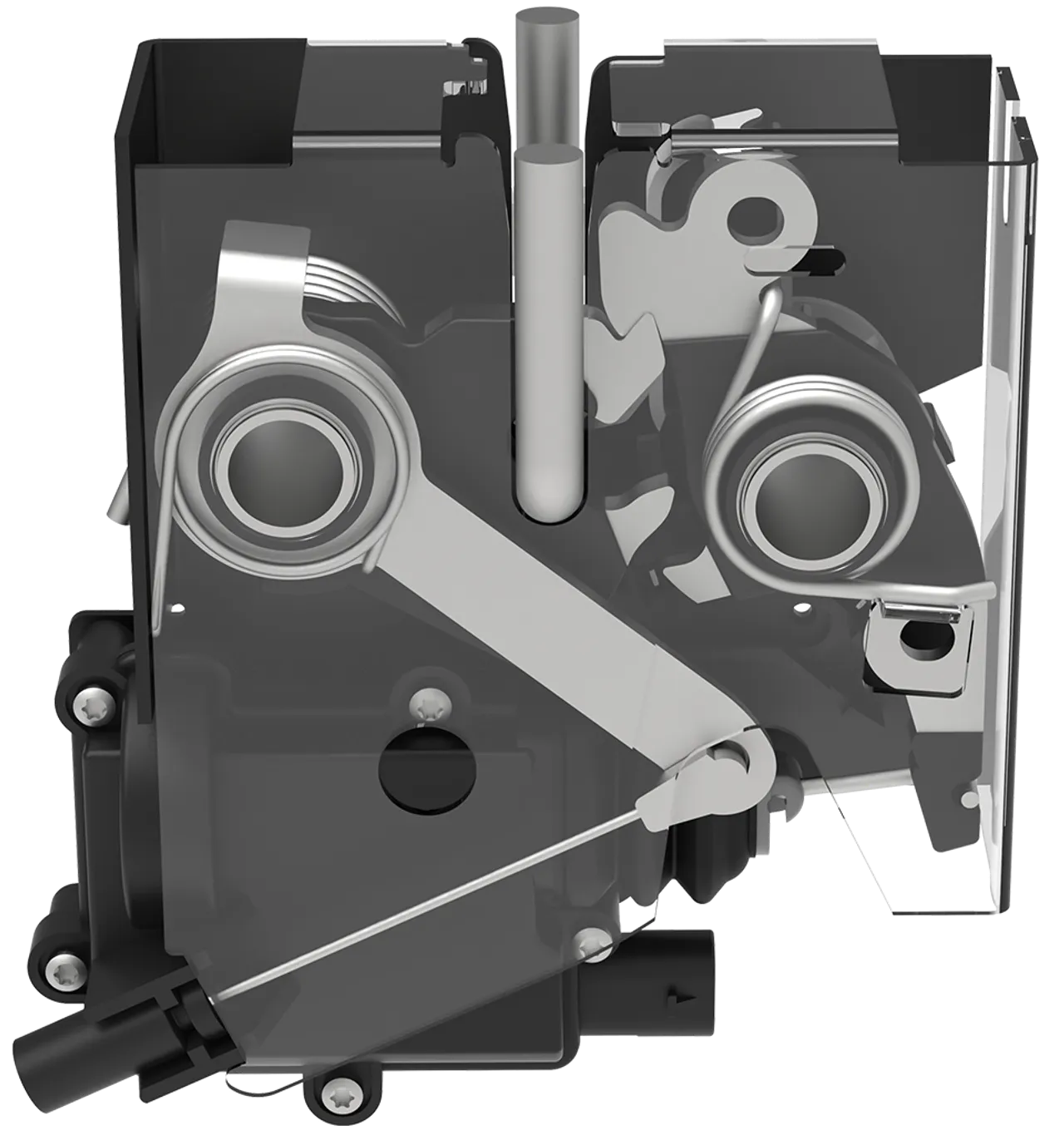

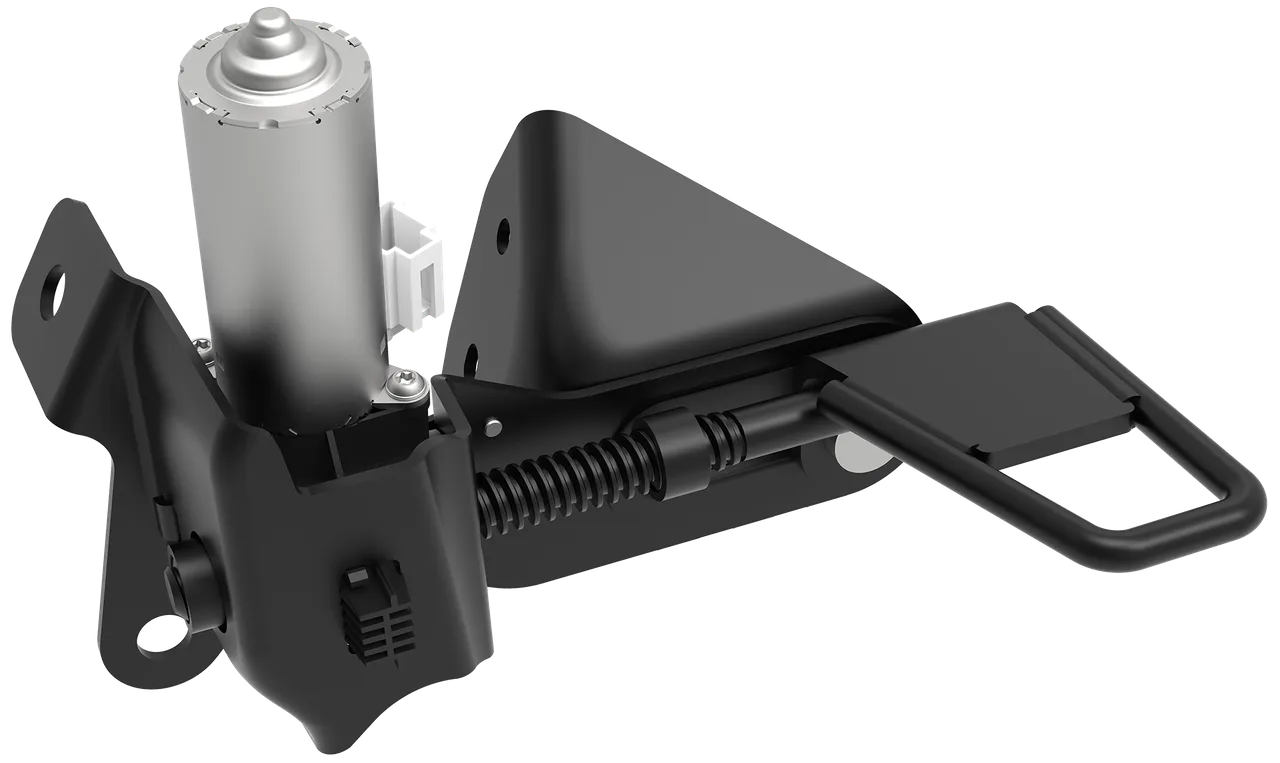

Electrical charging modules

Suitable for BEVs and automatic charging. Available with side or upward movement directions. Semi-automatic or fully electric drive. Proprietary silent Push-lock system.

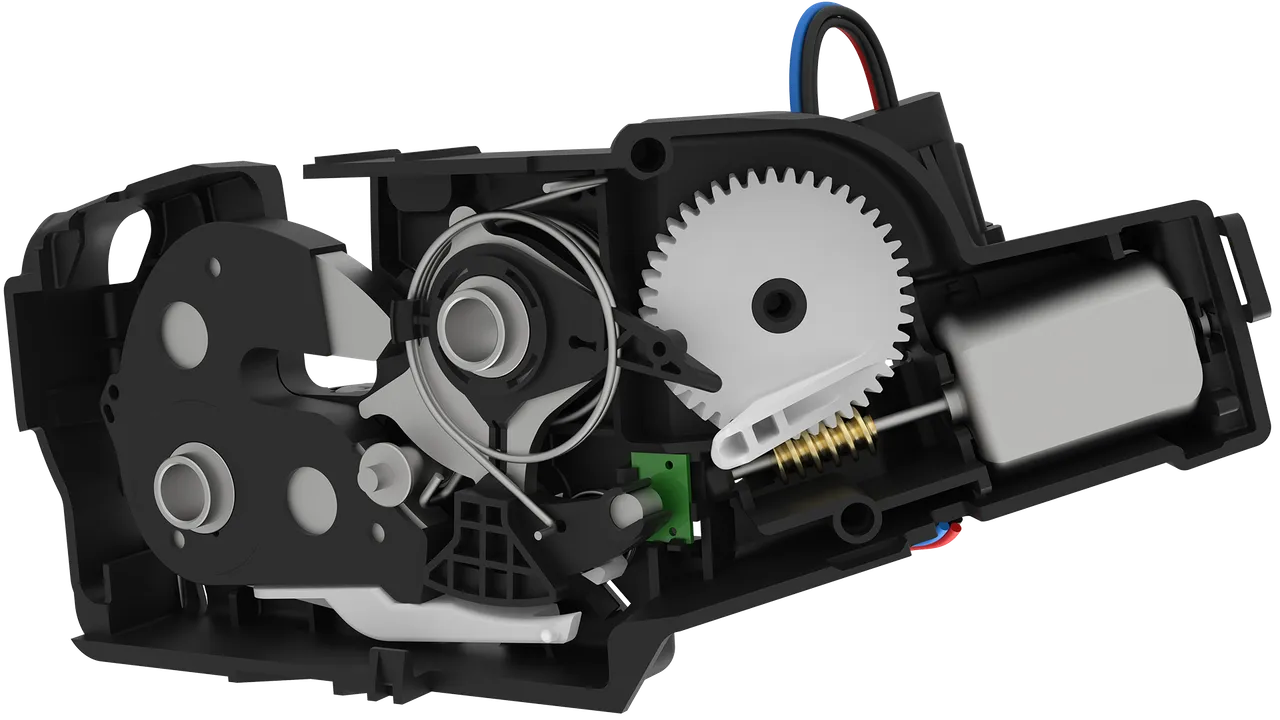

Push-push openers

Dual press system (close/open)

Case studies

Interactive browser

Take a look inside

Trusted by customers worldwide

Looking for a solution, need advice?

Our team is ready to help you.

sales@brano.euWhere to next?

Discover BRANO product portfolio