BRANO Technologies

Thanks to our extensive vertical integration, we can efficiently manage the entire production process, from development through manufacturing to the final product.

Our proven practices and constant search for new opportunities for development move us forward.

Tool Room

SBU TOOLS is part of the joint-stock company Brano and has a long tradition as a significant supplier of high-quality tools for the automotive industry.

- Precision cutting tools

- Progressive stamping tools

- Plastic injection molds

- Production cooperation on our technologies

Foundry

SBU Foundry of BRANO a.s. is a manufacturer of castings with more than a century of tradition. It offers small-series and large-series production of ductile and malleable iron castings, including subsequent CNC machining.

- Castings for the automotive industry

- Components for construction scaffolding and formwork

- Castings for the electrical industry

- Castings for use in agriculture

- Castings for general use

Stamping

Pressing

- Automatic progressive presses including transfer technology - up to 1000 t

- Automatic presses for precise cutting - up to 400 t

- Subsequent operations - grinding, grinding, degreasing, etc.

Precise cutting

- Presses 250 - 400 t

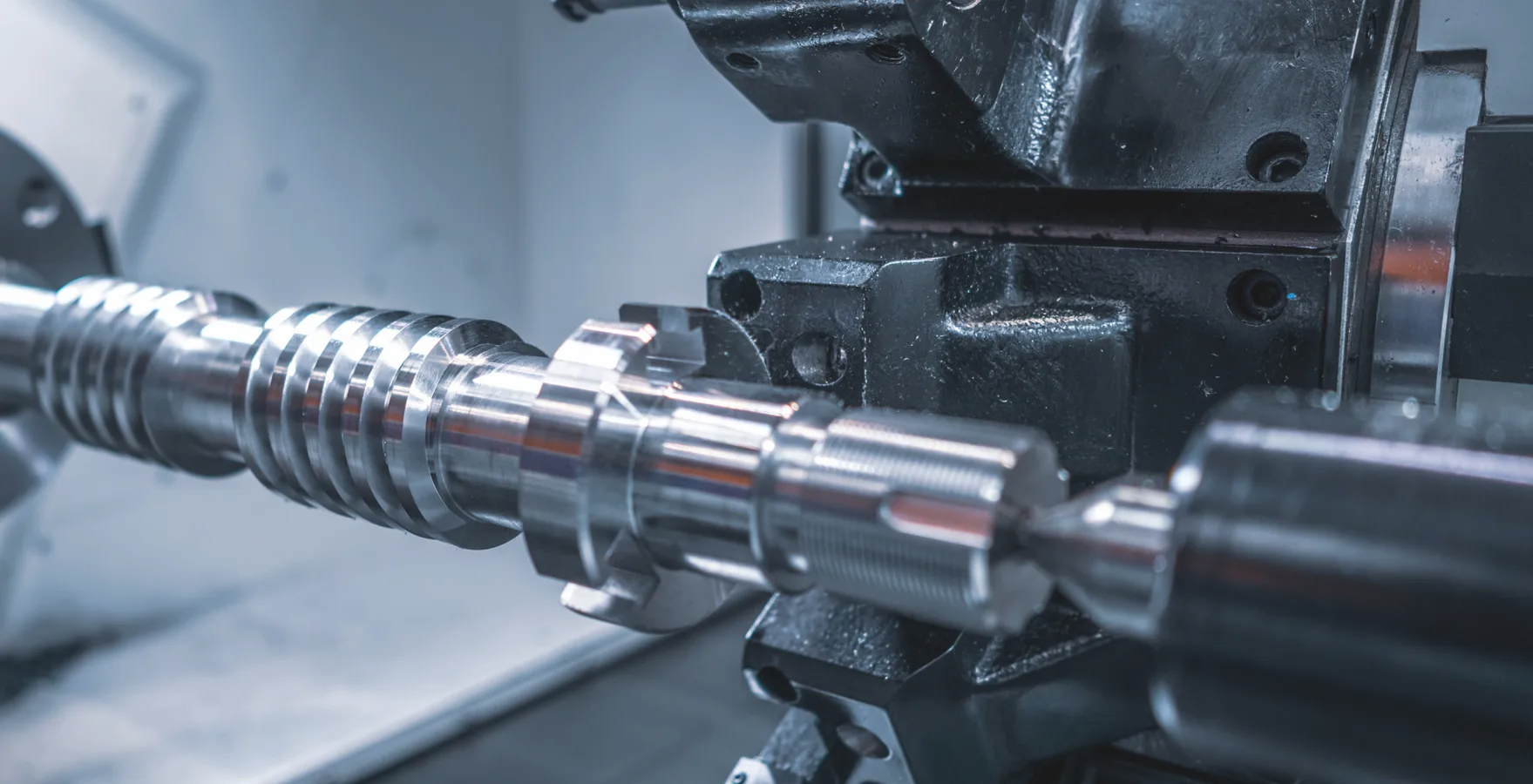

CNC Machining

- Conventional machining

- Turning

- Tumbling

- Polishing

- Machining

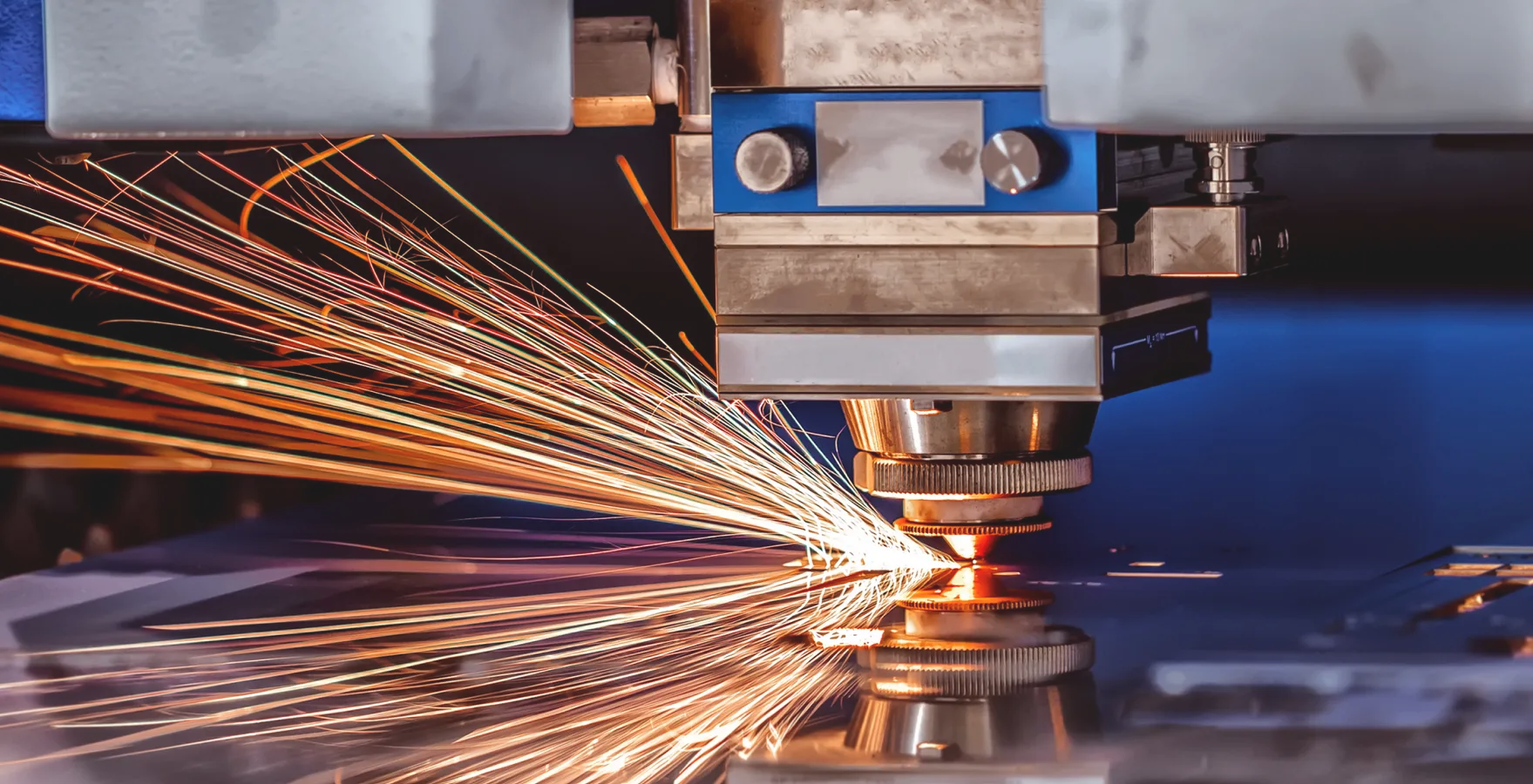

Laser cutting

- Sheet 2D lasers up to 20 mm thick

- Tubular 3D lasers up to 8 mm thick

Welding

- Spot Welding in CO2 Atmosphere

- Stainless steel welding

- Welding under a protective atmosphere

- Welding robots

Heat treatment and surface finishes

- Heat treatments - continuous and batch furnaces

- Surface finishes - cataphoretic and powderautomatic lines

Injection

Molding of Plastics

We are a significant manufacturer of plastic components for Czech and foreign car manufacturers and export them to almost all European countries. More than 60 injection molding machines within the group with a tonnage of up to 650 t, including 2K technology meeting the highest automotive standards.

- Automatic workplace with robotic loading of blanks

- Central vacuum drying of granules

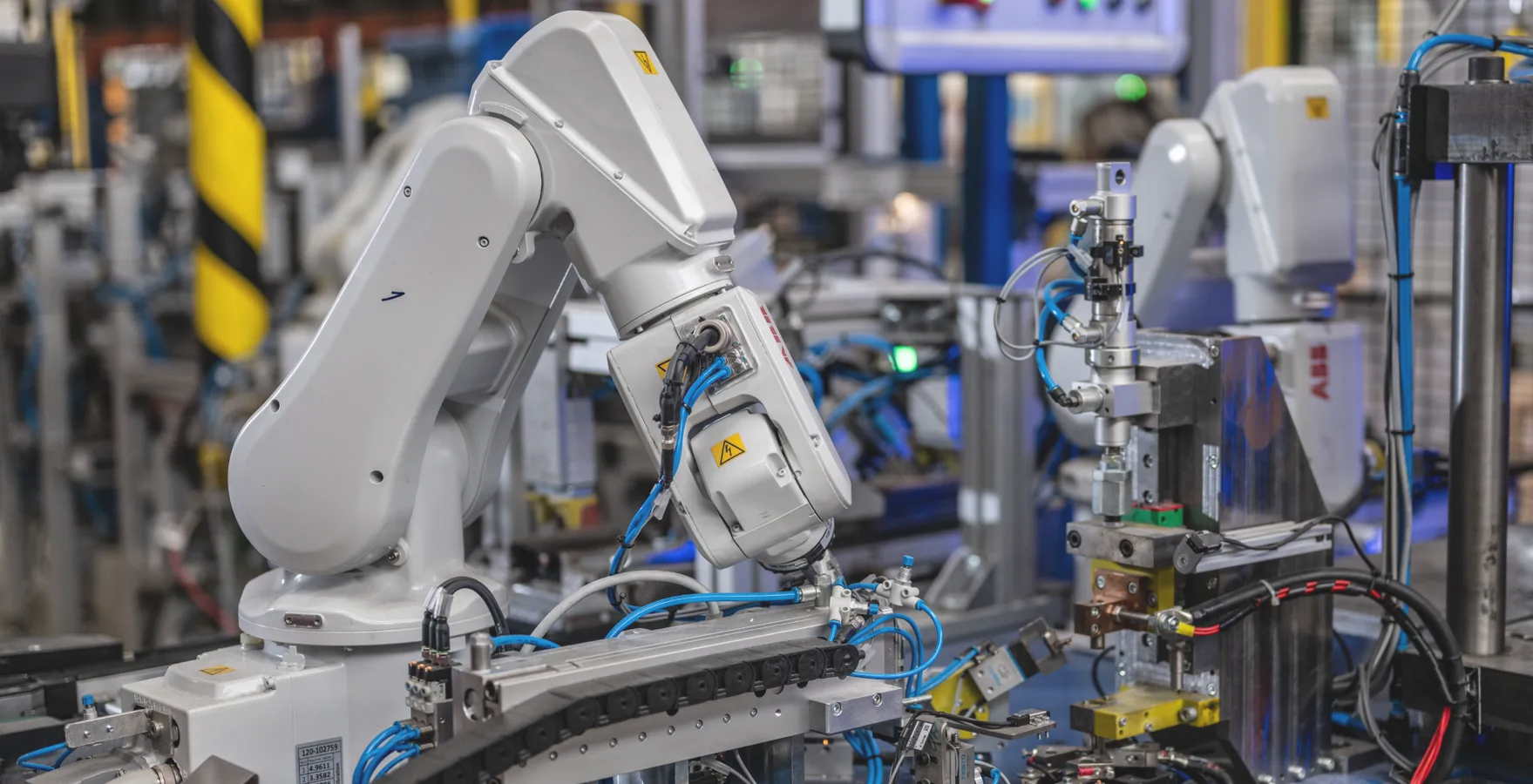

Assembly Lines

Automatic modular lines of our own production with high variability and fast availability according to customer requirements. We integrate all necessary technologies for our products into our production facilities - soldering, resistance welding, automatic lubrication, riveting, laser marking, etc. High production quality is ensured by advanced camera controls and sophisticated EOL (end of line) testers that verify 100 % of our production and record all production information.