BRANO Development Center

Development and testing of automotive products

Design of manufacturing processes

Tool design

Development and manufacture of production lines

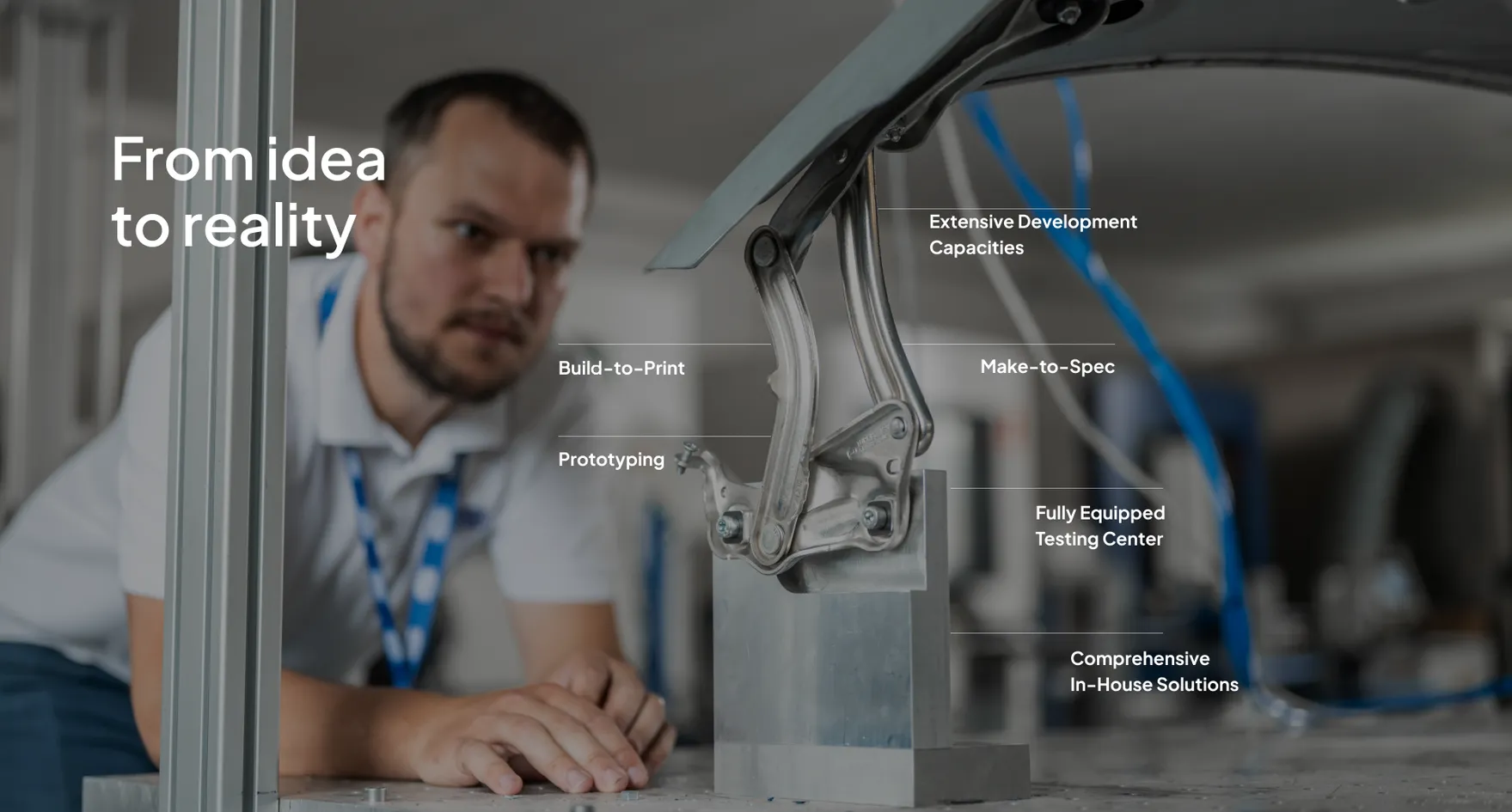

Development competencies

Thanks to an experienced development team, modern technological facilities, and a rich pool of employees, we are able to meet our customers' requirements for both Build-to-Print and Make-to-Spec manufacturing processes.

Build-to-Print

Make-to-Spec

Reverse Engineering

Prototyping

Industrialization (Industrial Design)

From idea to reality

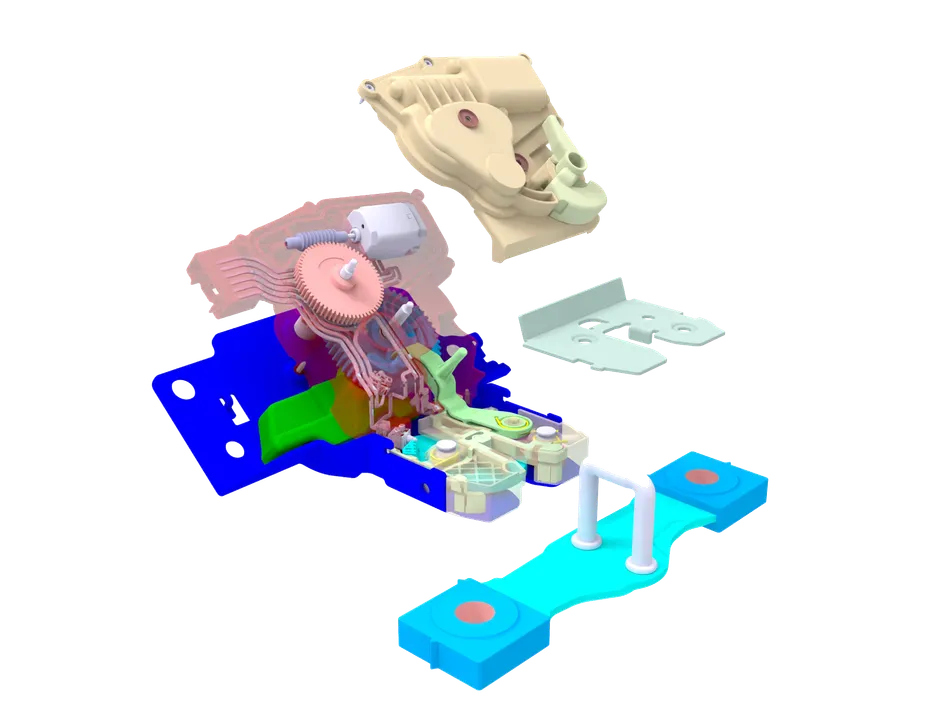

Fullservice Design

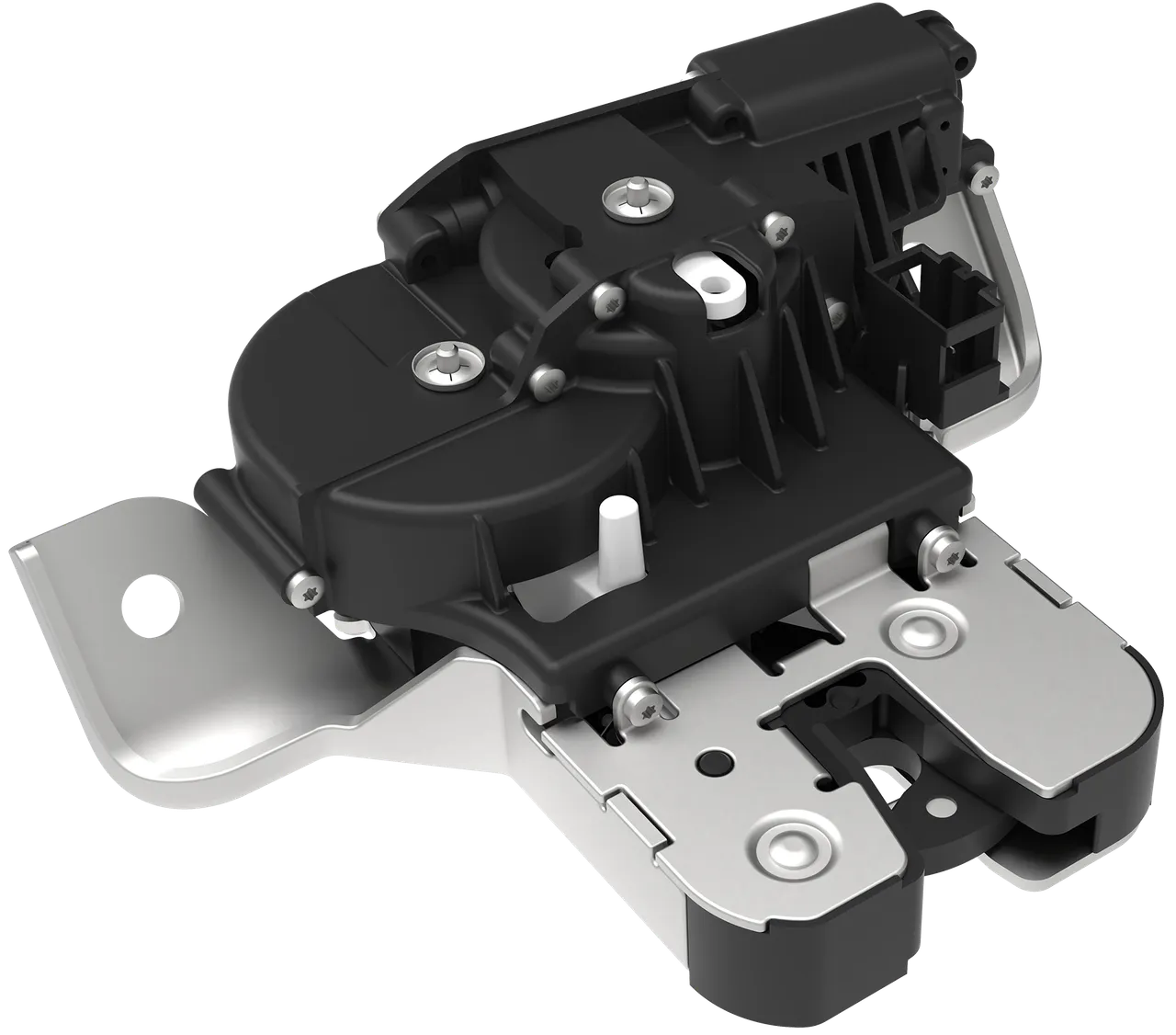

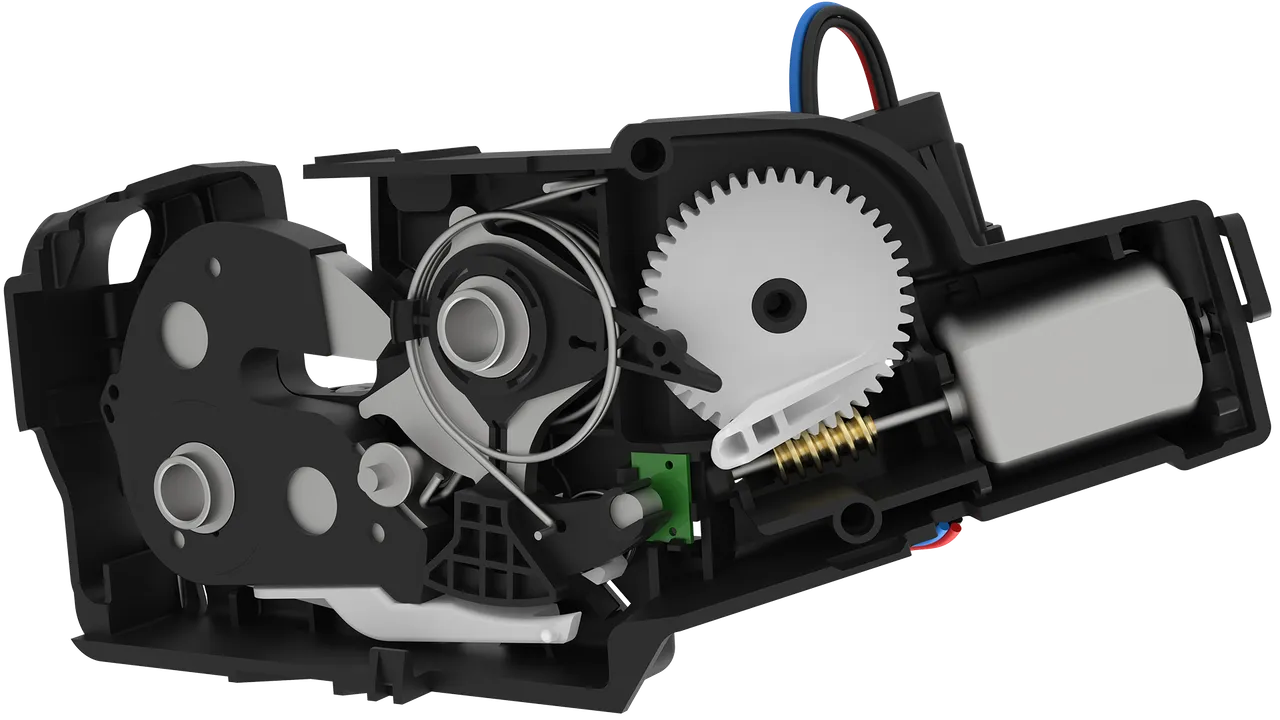

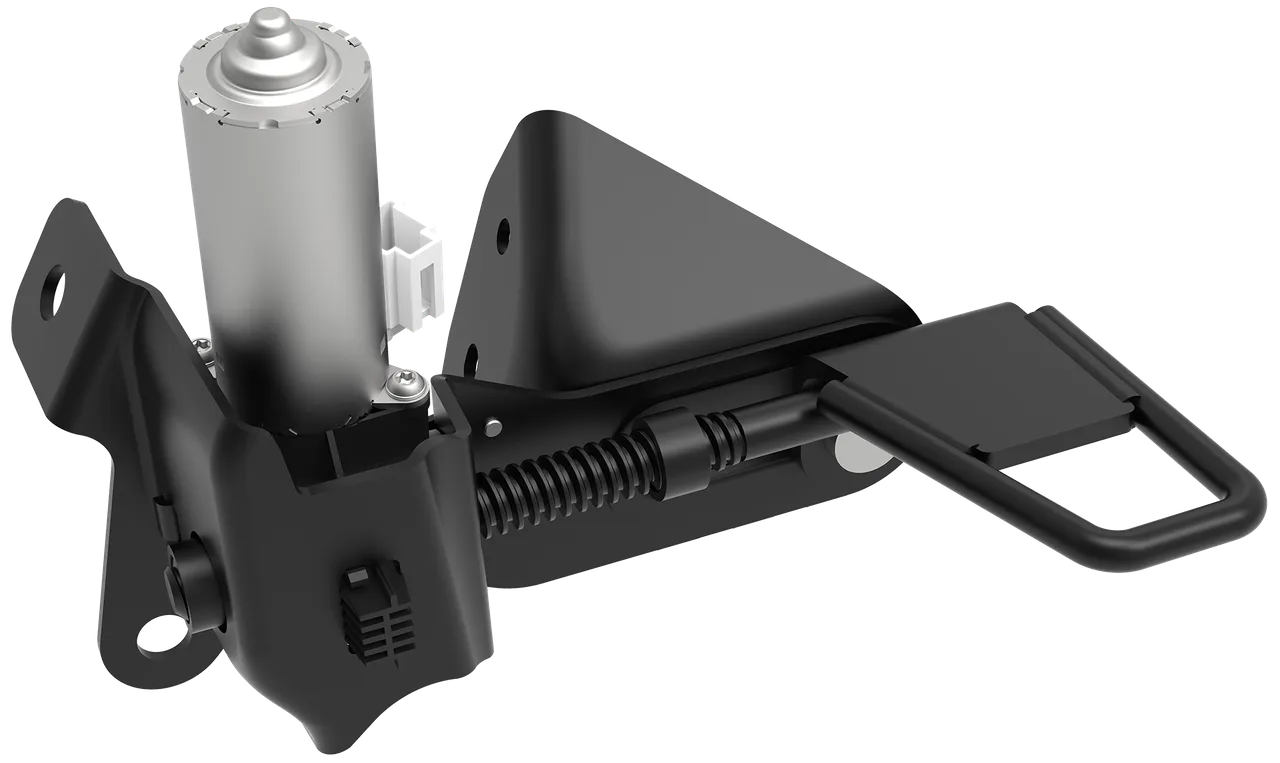

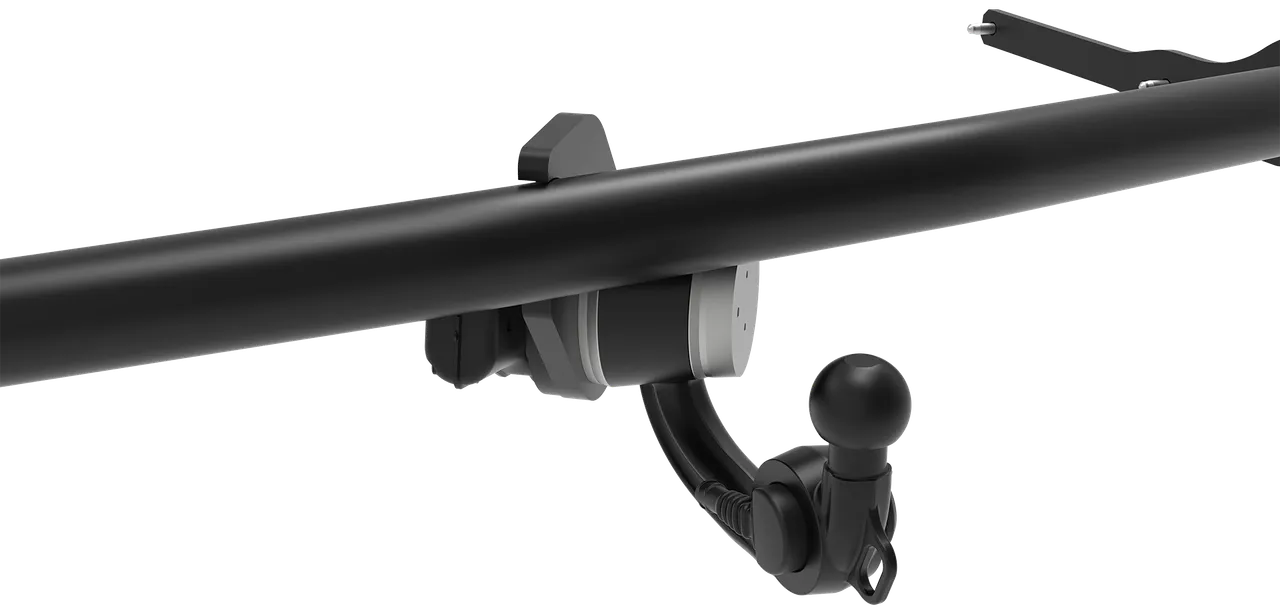

We provide our customers with a comprehensive service in product development. From conceptual design of assemblies, through individual components, to prototypes and full series design verified by all available simulation methods, ensuring the product meets the high demands of our customers.

In the design phase, we utilize software such as CATIA, NX, Enventive, and Kissoft.

In the design phase, we utilize software such as CATIA, NX, Enventive, and Kissoft.

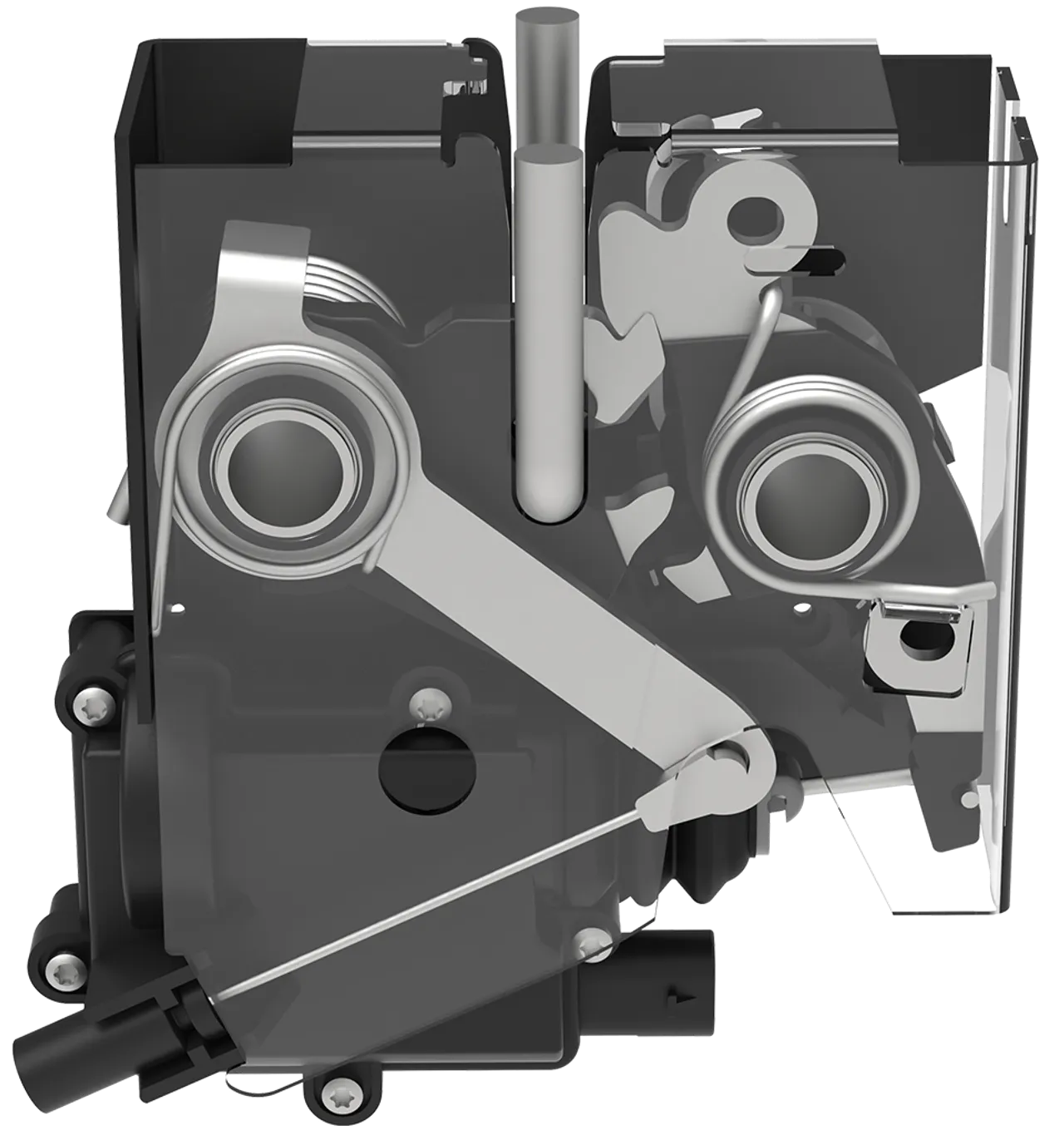

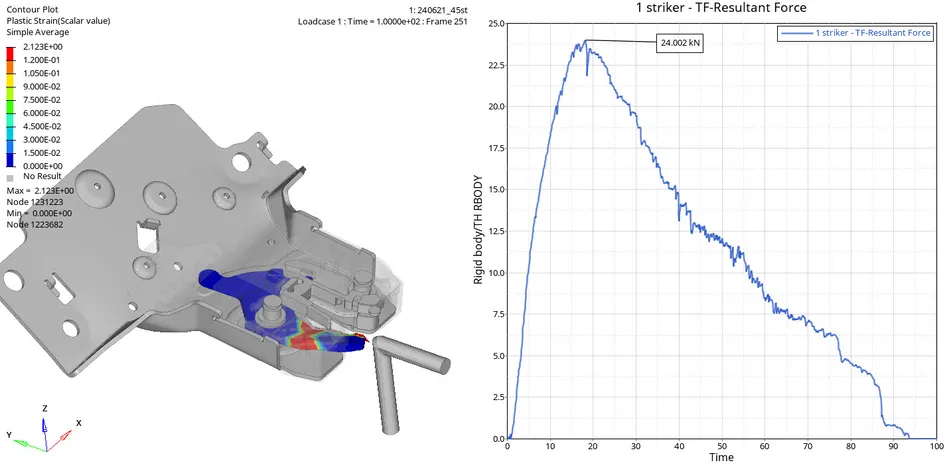

Simulations

We perform static, dynamic, explicit (crash), implicit, and non-linear tasks. Calculations are carried out for different ambient temperatures, including fatigue analysis. For FEA (Finite Element Analysis) calculations, we use software from Altair and MSC Software. For plastic injection molding simulations, we use the advanced tool Moldex3D. All these calculations are supported by a powerful computational server.

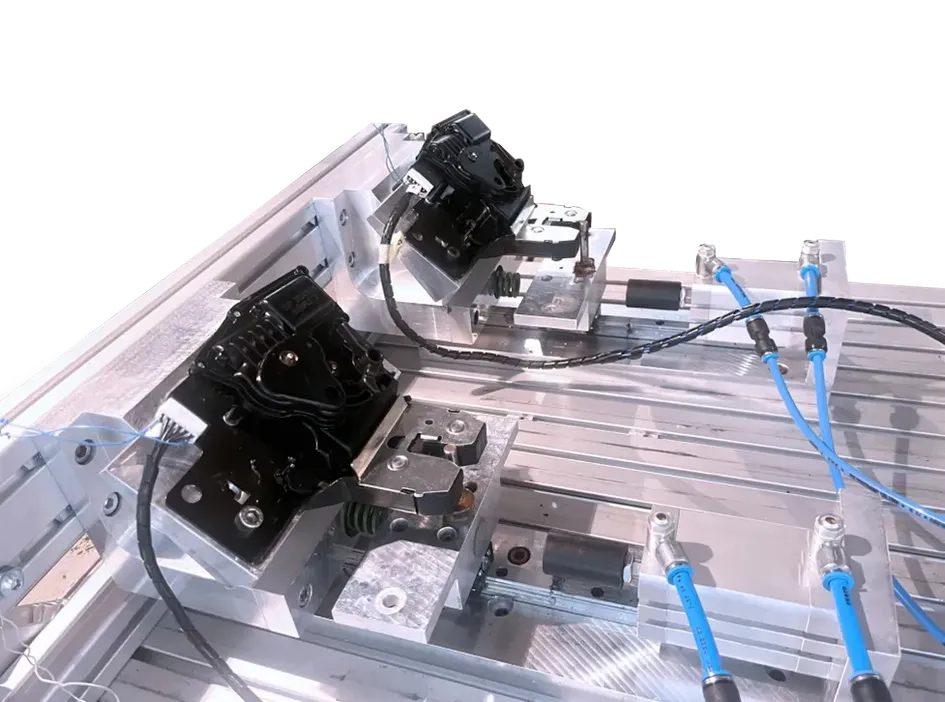

Testing and prototyping

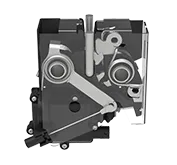

We carefully manufacture all prototypes for our customers using our in-house technologies, from metal stamped parts to injection-molded polymer components or machined parts. Heat treatment of steel components and surface painting are integral to our processes.

Most testing is conducted in our own laboratories, where we have access to unique, specialized testing equipment, as well as Weisstechnik climate chambers, Q-FOG corrosions cambers, tensile strength machines.

Most testing is conducted in our own laboratories, where we have access to unique, specialized testing equipment, as well as Weisstechnik climate chambers, Q-FOG corrosions cambers, tensile strength machines.

Case studies

Technological

Background

Background

Trusted by customers worldwide

You might be interested in

Where to next?